Design and Delivery of 2-Layer Attachment Interface PCB

Project Summary:

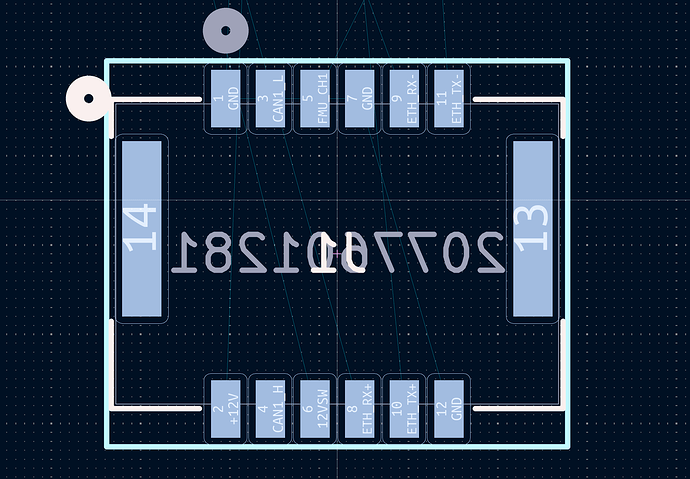

PT3 will require a custom design Attachment Interface PCB to fit the updated communication and power needs for different attachments. We are in need of a two standalone 2-layer Attachment Interface PCB. These boards will facilitate robust, modular connections between our Quiver platform and various payload attachments.

Project Scope:

PCB Requirements:

Electrical Requirements:

- Power distribution from the Main PCB to payload attachments.

- Support for signals required by payload attachments (ethernet, CAN, analog).

- Single output for 12V switched output.

The PCB will interface with the following 10 pin connector on the Main PCB

Design Files & Documentation Required:

- Schematic files (KiCAD)

- PCB layout files

- Gerber and drill files ready for fabrication

- Detailed Bill of Materials (BOM) with component sourcing links

- Information note including assembly instructions or notes where necessary

Acceptance Criteria:

- PCB passes Design Rule Checks (DRC) and Electrical Rule Checks (ERC).

- Gerber files are verified and ready for fabrication.

- All specified mechanical dimensions and electrical interfaces meet provided specifications.

- BOM is complete, accurate, and includes readily available components.

- Clear, readable documentation included.

Deliverables:

- Final schematic files

- Final PCB layout files

- Fabrication-ready Gerber files

- Drill files

- Comprehensive BOM

- Documentation with assembly and integration notes

Timeline:

- Start date: 2025-05-28T13:30:00Z

- Expected completion:2025-05-30T04:59:00Z

Payment Terms:

- Total bounty: $100 USDC (bounty worker can request a percentage in $ARROW token)

- Payment upon verification and acceptance of all deliverables

Application Procedure:

Message technical contact via email or Discord DM

Technical Contact:

@Kellan_C the bounty is ready!

potential issue here with the connectors chosen, they’re only rated for about 100 mating cycles. which would mean the contacts would need almost semi regular replacing not ideal DFM wise

1 Like

Erick,

Question on this design. I am seeing the part is a 12-pin connector, but we have 3 ground pins in this design. Is that intentional? Or would you like to see the 10-pin equivalent of the Molex connector with just one ground line?

@errrks.eth

1 Like

I am now also seeing that. Perhaps this may be the wrong part for the job?

Reading through the docs:

Please do not expose a product and a harness half-finished goods to the following condition.

・Dust

・Corrosive material

・Corrosive gas

・High temperature and high humidity

・Direct sunlight

and later on

3-7. Use of the product

1. This product is not designed and produced for the machine to be used under the condition involving human lives

or for the use of system. If you use this product for special use such as medical, aerospace and nuclear power

etc., please confirm us before using.

2. Please contact us without fail before using if you plan to use the product for automobile and ship etc. (We will

consider if the product can be applied to such specification condition.)

3. Please avoid using the product outdoors or under similar environment.

I am understanding that they are basically begging us to not use this for an outdoors-oriented drone-like application. If the intention is to have a fast-release, locking, compact connector, should I look for a different part?

@errrks.eth

1 Like

There is only one ground pin. The two additional pins that go to ground are the mounting pads (MP) for the connector. This is to increase the solder surface so they are better secured when someone pulls on the connector. Julius connected them to ground because “not connected” pads are easier to rip off.

So while only 10 pins are coming off the PCB I would like to still use the 12 pin connector and have an extra pin for 12V or 12VSW and GND. @Julius and @alperenag are y’all okay with this plan?

1 Like

Yeah not ideal but this is only an application for PT3 and additional sealing will be applied to the the connectors to help with environmental hazards. Feel free to propose an alternative but I would still like to see a version with the requested connector.

It looks like that is not quite right. The footprint for the 12 pin connector shows 14 total connections, 12 pins plus the 2 MP. This means that unless they are assigned elsewhere, there are 3 ground pins plus the 2 MP which could also be connected to ground.

Hi all,

Before I submit all of the final files, I want to make sure that the current approach is going to work with the project requirements.

This PCB actually has 2 pin headers, the pogo and the spring loaded receiver, both on the same side. The reason for this is that the end user can choose to populate one or the other to fulfill whichever side of the board they need, therefore only ever needing this single PCB.

Attached are screenshots of the schematic, PCB layout, and 3D model. Please let me know if I should proceed.

@errrks.eth

I think I misunderstood your first question. I thought you were referring to J31 & J39.

For this footprint, I would like to see the 10 pins from J31 & J39, 2 additional pins for 12V and GND, plus the 2 MP pins.

Does that make sense?

I am fine with this change as long as it fits into the quick release plate. It is a nice touch. Thank you!

Still no, because the requirement at the top asks for a 12 pin Molex header. In addition, J31 already includes 12V and GND, so it is not clear if you want to double-up on those two.

Where should I leave the documents?

Yes, I would like to double up on 12V and GND. That way we have extra power for whatever payload gets attached.

You can open a PR to upload the files here: project-quiver/task-grant-bounty/pt3/electronics/0003-Attachment-Interface-PCB at main · Arrow-air/project-quiver · GitHub

Please also fill out the information note! You can read the AIP and use this an example.

Closing topic. Bounty has be merged into Main Project Quiver Repo.